Quality Control

We protect our customers by carefully selecting and continuously rating suppliers. All parts we sell go through a rigorous testing procedure by qualified electrical engineers. Our professional quality control team monitors and controls quality throughout the entire process including purchase, storage and delivery.

Visual inspection

A stereomicroscope provides a 360° view of the component’s appearance. Key points to observe the status include product packaging; Chip type, date, batch; Printing and packaging status; Pin arrangement, coplanar with the plating of the case, etc. A visual inspection can quickly understand the requirements to meet the external requirements of the original brand manufacturer, anti-static and moisture standards, and whether to use or refurbish.

Weldability test

This is not a counterfeit detection method because oxidation occurs naturally; However, it is an important functional issue that is particularly prevalent in hot and humid climates such as Southeast Asia and the southern states of North America. Joint standard J-STD-002 defines test methods and acceptance/rejection criteria for through-hole, surface-mount, and BGA devices. For non-BGA surface-mount devices, an immersion appearance is used, and “ceramic plate testing” of BGA devices has recently been incorporated into our service suite. Solderability testing is recommended with unsuitable packaging, acceptable packaging but equipment that has been in use for more than one year, or display contamination on pins.

X-ray

X-ray detection, 360° transverse observation of the internal parts to determine the internal structure and package connection status of the components under test, you can see whether a large number of samples under test are the same, or mixed (mixed) problems; In addition, they also interact with the specification (data sheet) to understand the correctness of the sample under test. Test the connection status of the package, to understand whether the connection between the chip and the package pin is normal, eliminate the key and open circuit short circuit.

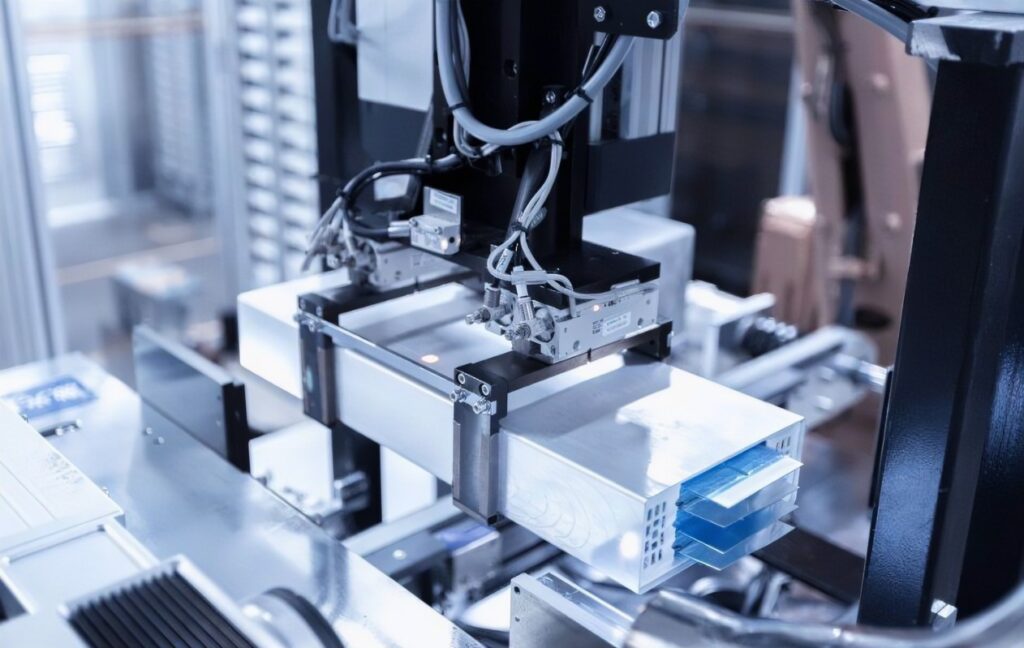

Functional/programming test

Through the official data table, design test projects, develop test boards, build test platforms, write test programs, and then test various functions of IC. Through professional and accurate chip function testing, you can identify whether the IC function is up to standard. Currently, the types of ics that can be tested include: logic devices, emulators, high-frequency ics, power ics, various amplifiers, and power management ics. The package covers DIP, SOP, SSOP, BGA, SOT, TO-220, QFN, QFP, etc. We use programming equipment that supports the inspection of 000,208 IC models from 47 manufacturers. Products include: EPROM, parallel and serial EEPROM, FPGA, configured serial PROM, Flash memory, BPROM, NOVRAM, SPLD, CPLD, EPLD, microcontrollers, MCUS, and standard logic device inspection.